We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

Use our expertise to outpace competitors and reach customers faster. We'll adapt our technologies to your needs and help with integration.

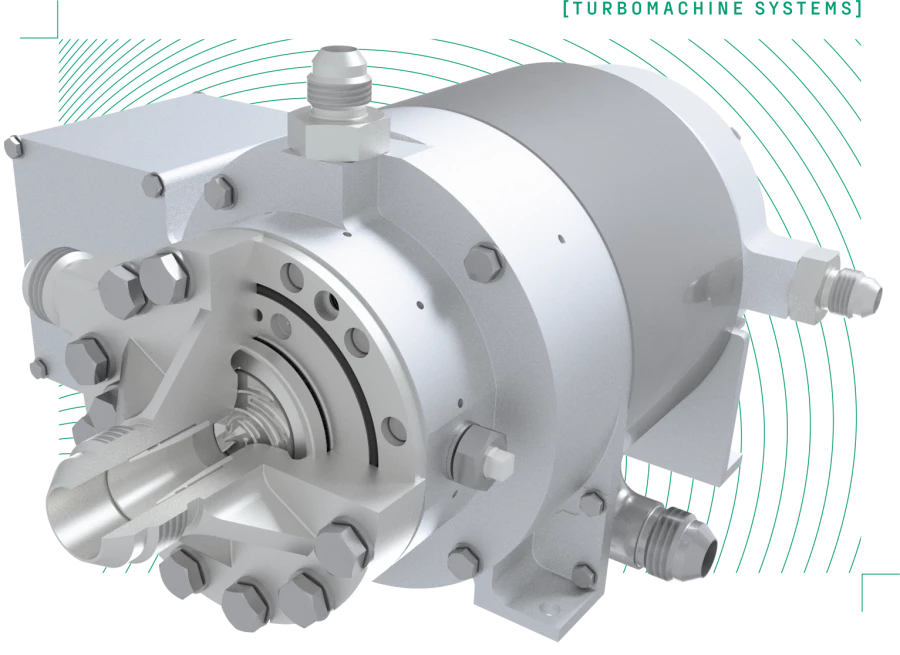

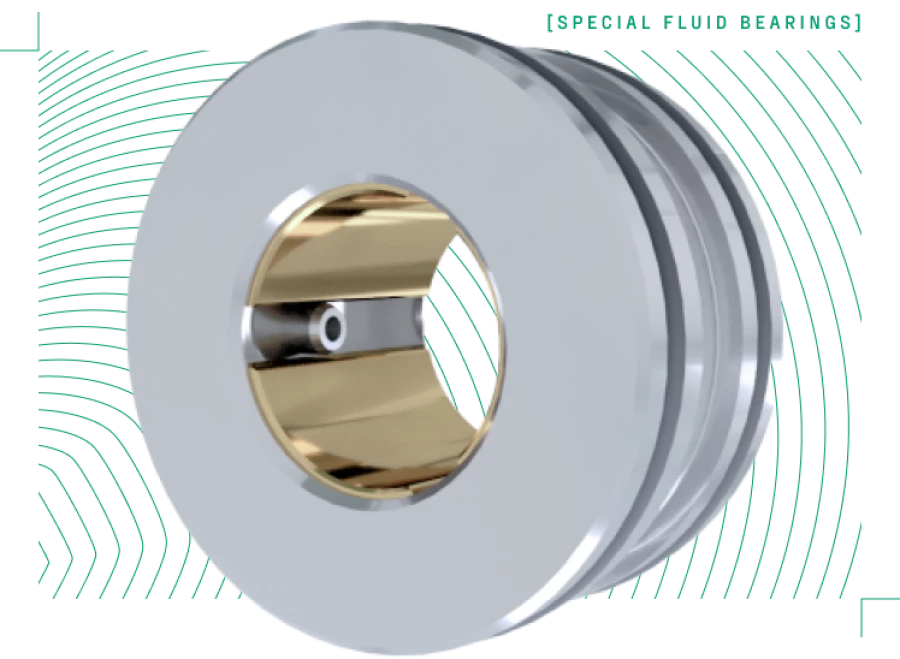

Engineering of customized machines with fluid-lubricated bearings for researchers and developers working with low-viscosity and gaseous media.

High-tech space-derived systems may benefit businesses and society by improving lifetime, minimizing resource demands, and reducing pollution if applied to non-space environments.

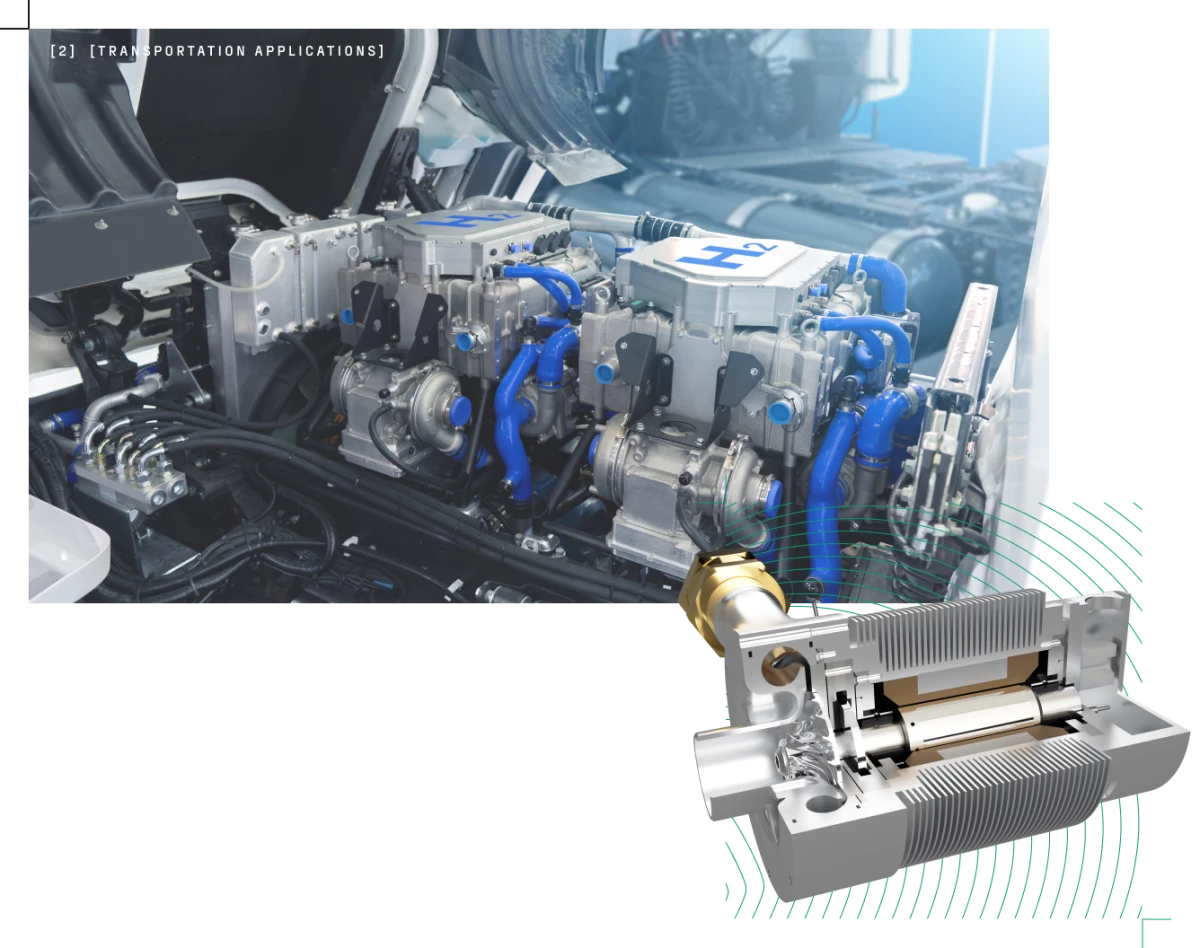

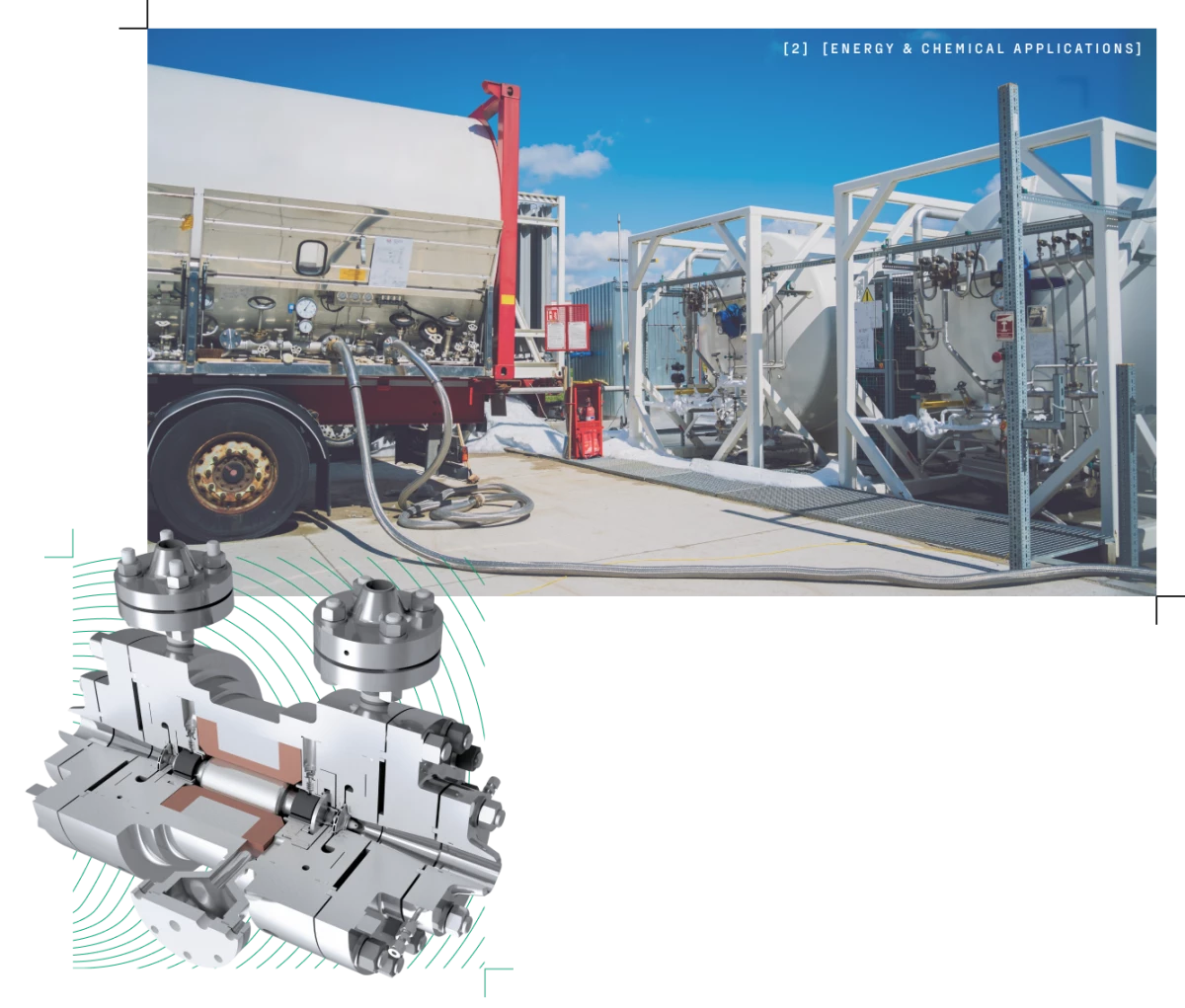

High-speed electric pumps

Electric compressors

Turbines and generators

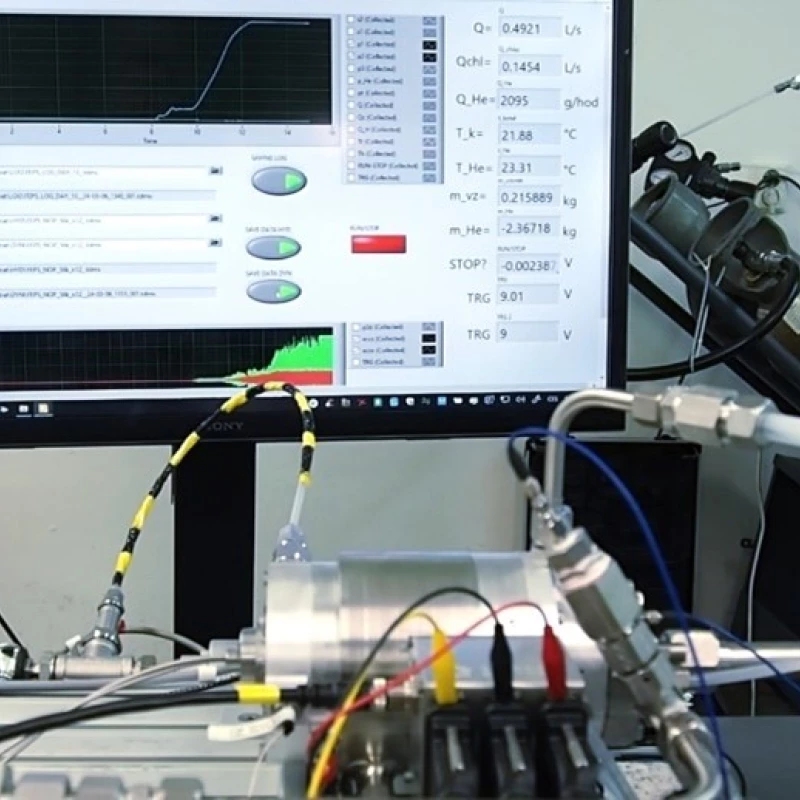

Test and measuring machines

Gas aerodynamic bearings

Low-viscosity hydrodynamic bearings

Gas aerostatic bearings

We identify advanced technologies, formulate innovative design concepts, and assess feasibility.

Precision prototypes are manufactured, designs undergo iterative validation and are refined based on feedback.

Performance is rigorously evaluated, assessing efficiency and reliability. Design parameters are adjusted as required.

We optimize manufacturing processes, validate quality, and ensure consistent performance for broader deployment.

Whether you need complex idea validation or just a second pair of eyes, reach out – our experts are always on your side. Feel free to consult us for assistance with feasibility, optimization, calculations, troubleshooting, system integration, and more.

Contact us

Explore exciting job opportunities that match your skills and ambitions. Join a dynamic team where innovation thrives, and your contributions make a real impact. Your next career move awaits – discover it with us.