We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

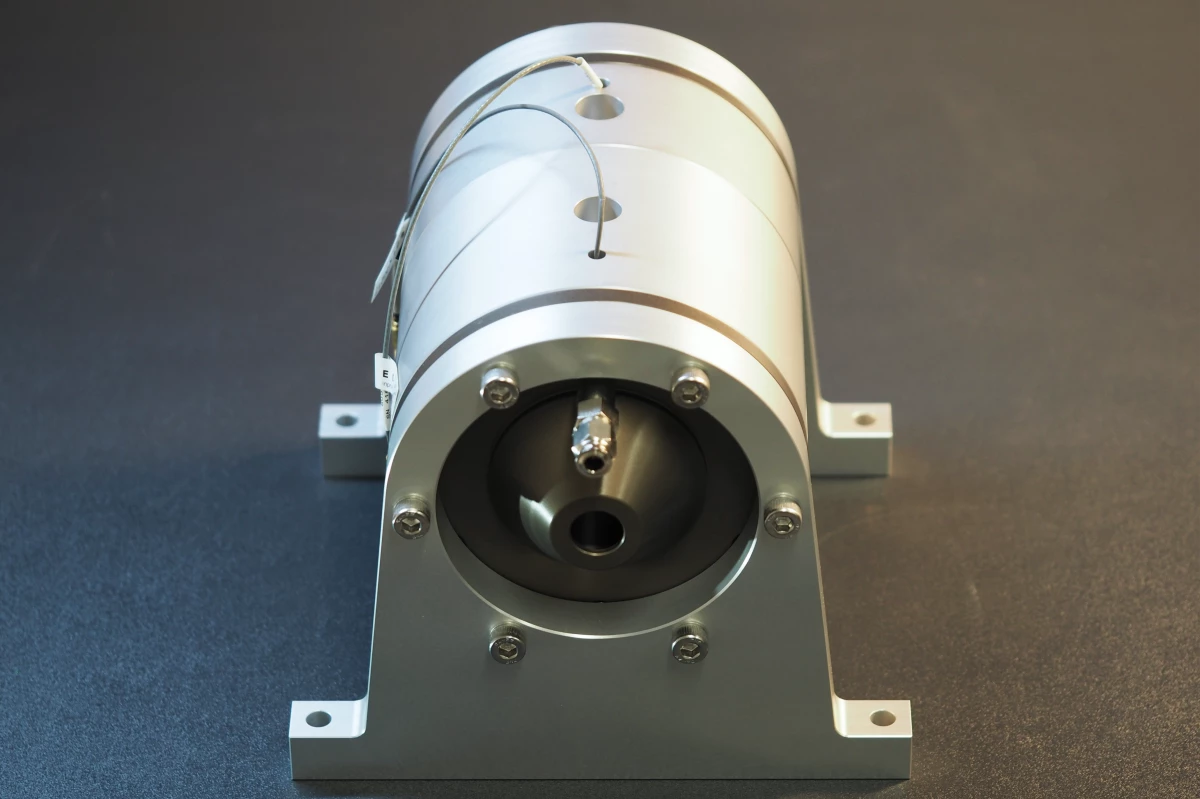

Rotating machines

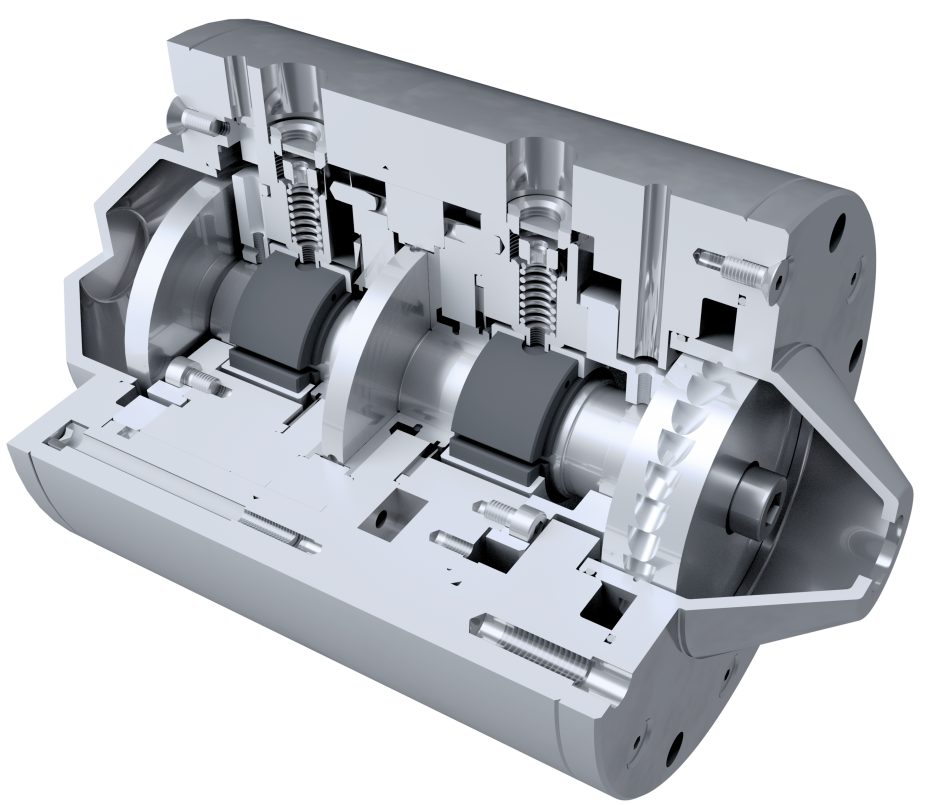

Electrically driven turbochargers and compressors offer versatile and hermetically sealed operation across a broad temperature spectrum, ranging from cryogenic to high-temperature applications. They demonstrate exceptional performance as standalone systems or when seamlessly integrated into vacuum or high-pressure machines, owing to their ultra-low friction and high reliability.

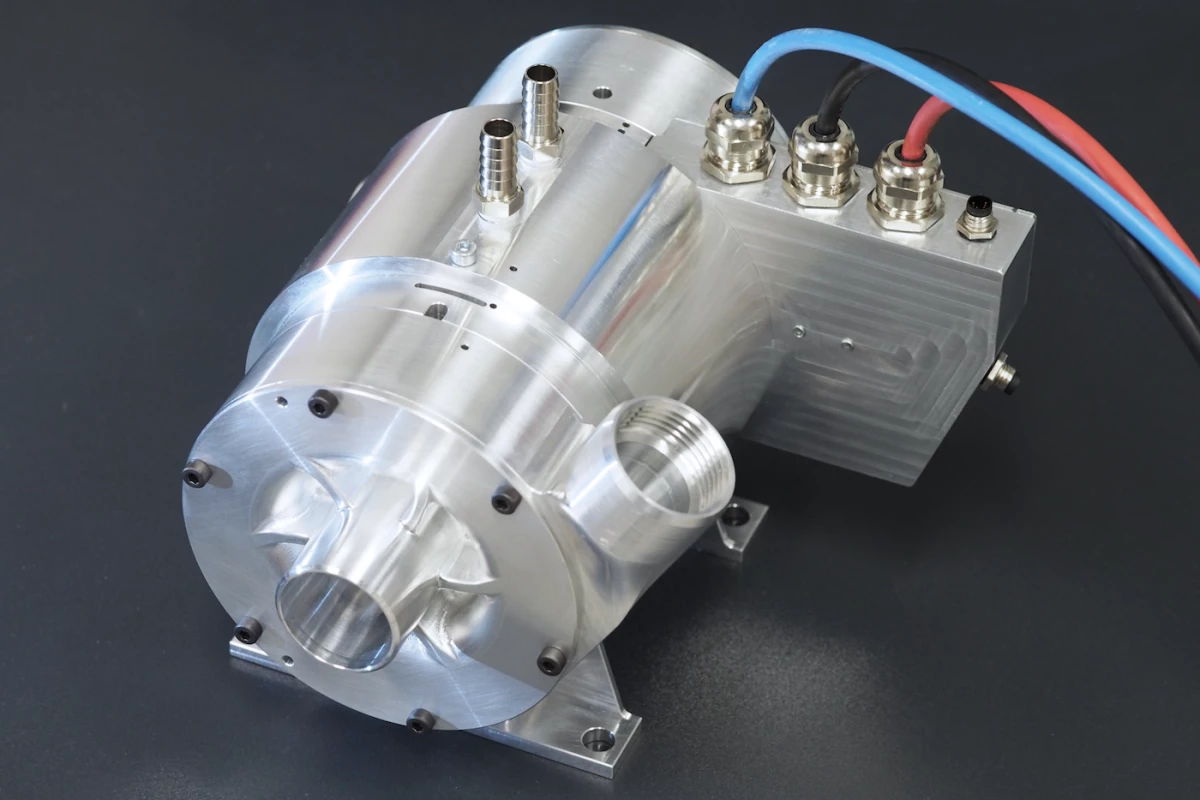

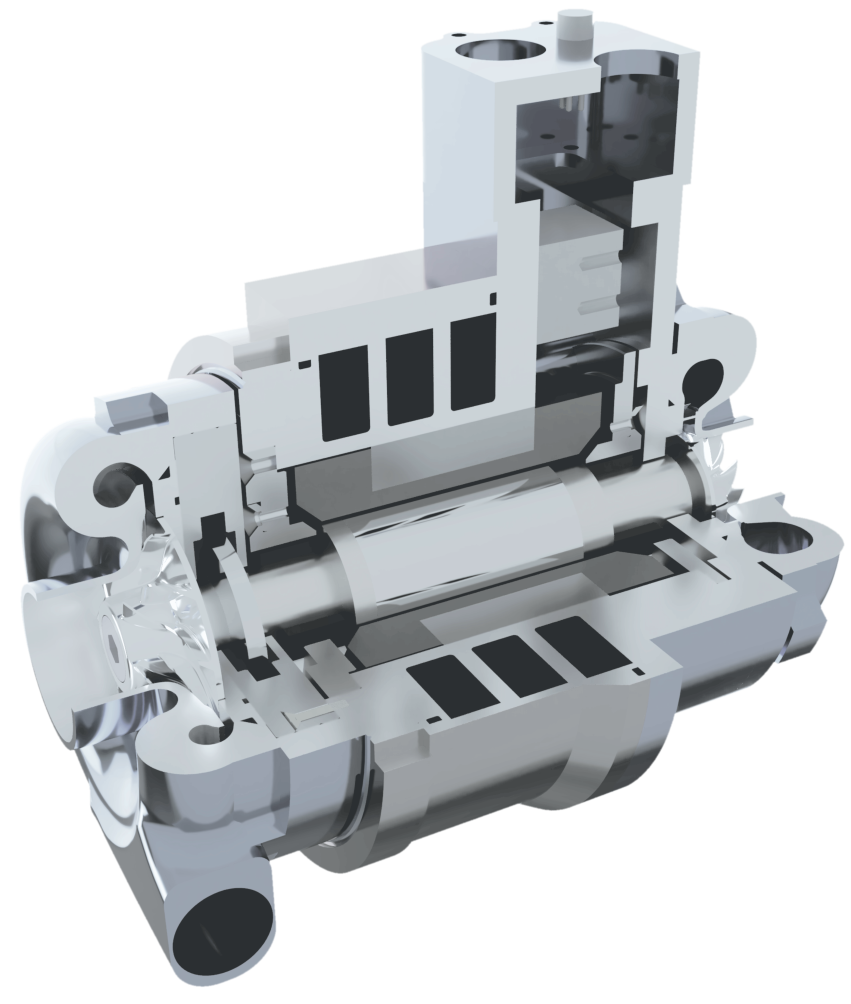

Compressors for fuel cells are crucial in ensuring the optimal performance of fuel cell systems. These electrically powered turbochargers and compressors play a vital role in delivering compressed air to the fuel cell stack, where oxygen is extracted from the incoming air for the cathode reaction. The quantity and purity of the air supplied are paramount for the efficiency and reliability of fuel cell systems, as contaminants can be detrimental to the performance of fuel cells. Factors like compressor weight, response time, and operational noise levels are carefully considered to ensure seamless integration into fuel cell systems for transportation applications.

| Max. Pressure Ratio | 2.26 |

| Max. Mass Flow | 125 g/s |

| Max. Rated Input Power | 10 kW |

| Max. Rated Speed | 120 000 rpm |

| Isentropic Overall Efficiency | > 70 % |

| Dimensions | 110 × 180 × 230 mm |

| Target Weight (Without Inverter) | < 8 kg |

| Operating Voltage | 400 V |

| Max. Pressure Ratio | 2.3 |

| Max. Mass Flow | 45 g/s |

| Max. Rated Input Power | 6 kW |

| Max. Rated Speed | 160 000 rpm |

| Isentropic Overall Efficiency | > 70 % |

| Dimensions | 110 × 170 × 220 mm |

| Target Weight (Without Inverter) | < 8,5 kg |

| Operating Voltage | 400 V |

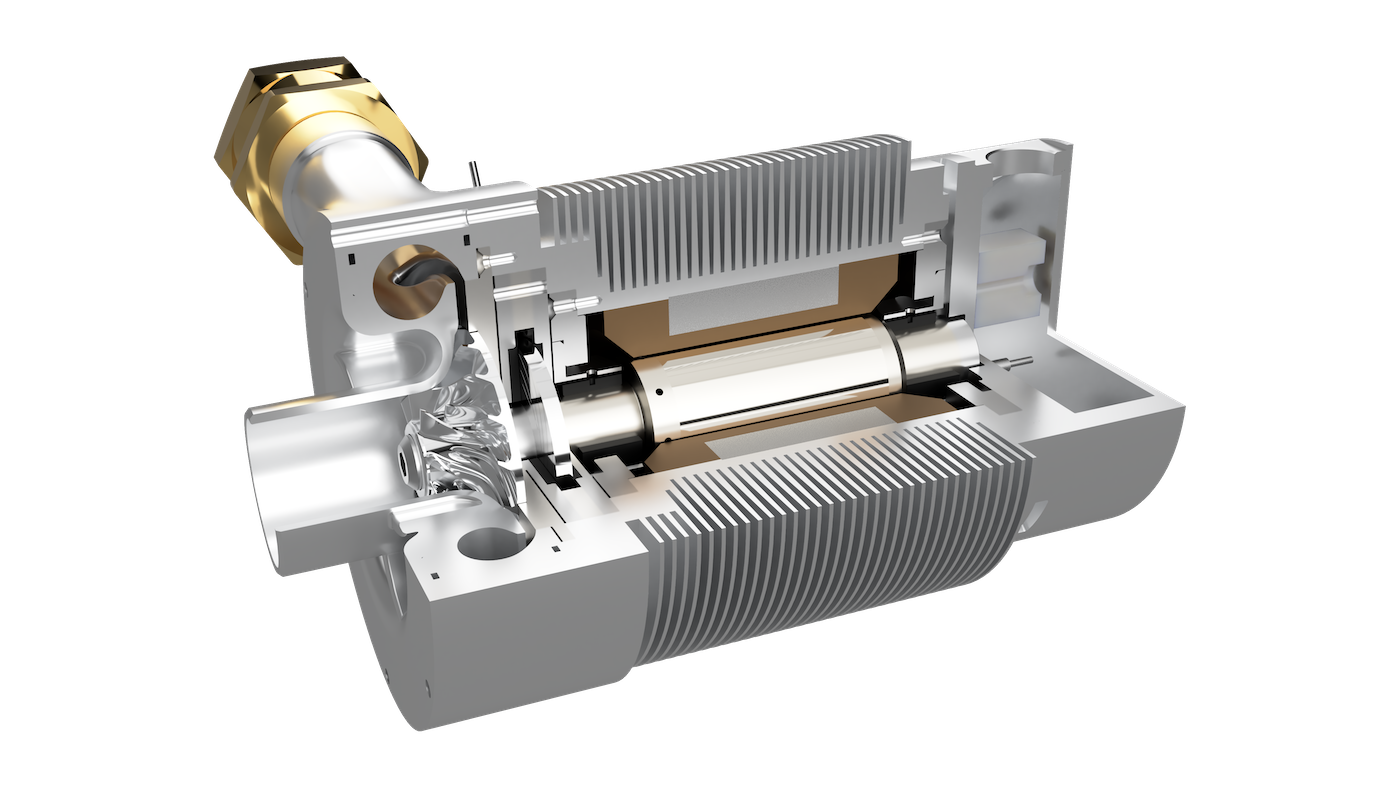

Companders and compressors, tailored for sCO2 technology, excel under demanding conditions, enhancing cycle efficiency. They optimize heat transfer, with high coefficients and impressive thermodynamic performance. Durability, low maintenance, and adaptability make them reliable and cost-effective solutions for power generation and waste heat recovery, promoting sustainability and environmental responsibility.

| Rotational speed | 26 000 rpm |

| Inverter input voltage | 400 V |

| Maximum Load Capacity | 12.26 N·m |

| Input power | 30 kW |

| Max. efficiency | > 80 % |